SEARCH RESULTS

-

- Item No

- 0000000910

- Type

- Tapping Center

- Maker

- BROTHER

- Model

- TC-S2DN-O

- MFG Year

- 2013

- Movie

- Yes

- Specification

- Yes

-

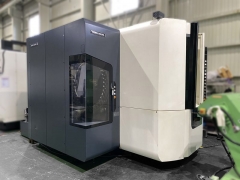

- Item No

- 0000000890

- Type

- Horizontal Machining Center

- Maker

- DMG MORI SEIKI

- Model

- NHX5000 2ndGe (NHX51180314)

- MFG Year

- 2018

- Movie

- Yes

- Specification

- Yes

-

- Item No

- 0000000975

- Type

- Horizontal Machining Center

- Maker

- MORI SEIKI

- Model

- NH4000 DCG

- MFG Year

- 2005

- Movie

- Yes

- Specification

- Yes

-

- Item No

- 0000000976

- Type

- Horizontal Machining Center

- Maker

- MORI SEKI

- Model

- NH4000 DCG

- MFG Year

- 2006

- Movie

- Yes

- Specification

- Yes

-

- Item No

- 0000000884

- Type

- Horizontal Machining Center

- Maker

- DMGMORI SEIKI

- Model

- NHX5000 2ndGe

- MFG Year

- 2017

- Movie

- Yes

- Specification

- Yes

-

- Item No

- 0000000979

- Type

- Horizontal Machining Center

- Maker

- MORI SEIKI

- Model

- NHX4000

- MFG Year

- 2011

- Movie

- No

- Specification

- Yes

-

- Item No

- 0000000996

- Type

- Vertical Machining Center

- Maker

- OKUMA

- Model

- MILLAC 561VⅡ

- MFG Year

- 2016

- Movie

- No

- Specification

- Yes

-

- Item No

- 0000000824

- Type

- Vertical Machining Center

- Maker

- OKUMA

- Model

- MILLAC-1052VII

- MFG Year

- 2017

- Movie

- Yes

- Specification

- Yes

-

- Item No

- 0000000902

- Type

- Vertical machining

- Maker

- Mazak

- Model

- FJV-200II

- MFG Year

- 2015

- Movie

- Yes

- Specification

- Yes

-

- Item No

- 0000000958

- Type

- Vertical Machining Center

- Maker

- MAZAK

- Model

- VCN 410B-II

- MFG Year

- 2007

- Movie

- No

- Specification

- Yes

-

- Item No

- 0000000957

- Type

- Vertical Machining Center

- Maker

- MAZAK

- Model

- VCN 515C-II

- MFG Year

- 2007

- Movie

- No

- Specification

- Yes

-

- Item No

- 0000000789

- Type

- Vertical Machining Center

- Maker

- MAKINO

- Model

- L2 (機番344)

- MFG Year

- 2016

- Movie

- Yes

- Specification

- Yes